Winners of the 2023York Chapter

Engineering Project of the Year Award

Engineering Research Project of the Year Award

2024 York Chapter Engineering Project of the Year Award is open for applications!

Large Projects Category

1st Place - Major Mackenzie Drive Reconstruction

York Region

Project Summary:

Major Mackenzie Drive is a major east-west arterial road under the jurisdiction of The Regional Municipality of York (York Region) and is one of the busiest corridors in the Region. Situated within the historic Village of Maple, in the City of Vaughan, the section from Jane Street to Keele Street provides access to critical infrastructure including Vaughan City Hall, Maple GO Station, Cortellucci Vaughan Hospital, Canada’s Wonderland, and Highway 400, as well as numerous plazas, businesses, and residents throughout, and is used by approximately 35,000 vehicles daily.

A need for various operational improvements along the corridor to better serve the community was demonstrated through a Class Environmental Assessment that included extensive community and stakeholder engagement. Construction on this critical project began in Fall 2022 and was expected to be completed in mid 2024. Recognizing the impact construction was having on the larger community due to several on-going major construction projects in Vaughan, the Region accelerated the Major Mackenzie Drive construction. Through the various acceleration methods, construction on this challenging corridor was completed ahead of schedule in December 2023 in the midst of a very busy construction season in Vaughan.

The project was innovative with construction methodologies such as those used to mitigate traffic impacts and reduce property requirements, transformed the corridor to better reflect the heritage character of the community, addressed sustainability by implementing active transportation facilities and roadway design that would require less maintenance in the long run, and ensured that the Region, and residents of Vaughan received a high-quality product at the end of construction that can be enjoyed by the community for years to come, resulting in an overall immense positive impact on the York Region community.

Medium/Small Projects Category

1st Place - Maximizing Energy Efficiency in Large Buildings

NERVA Energy

Project Summary:

The goal of this project was to collaboratively engineer, design, and implement a custom-tailored energy conservation program across Canada's 10th largest private real estate portfolio (Drewlo Holdings) of 85+ buildings, encompassing over 10,000 suites and 1,500+ mechanical systems, to meet their ambitious sustainability and performance goals.

NERVA Energy combined mechanical and energy engineering principles to evaluate system designs and efficiencies, introduced comprehensive submetering and developed an advanced intelligent controls package that allowed for custom operational scripts to precisely meet each building's thermal demands, addressing energy wastage and ensuring peak efficiency, resulting in maximizing energy efficiency across all systems and actionable insights for continuous improvement in energy performance.

The project was completed well ahead of schedule and led to a significant 36% reduction in GHG emissions and expected millions of dollars in annual utility savings. The project not only achieved exemplary energy efficiency for the client, but also set a new standard in integrated, intelligent energy management solutions, sparking further interest and investment in the green economy that could be applied to burgeoning communities in the GTA like York Region.

Engineering Research Project of the Year Award

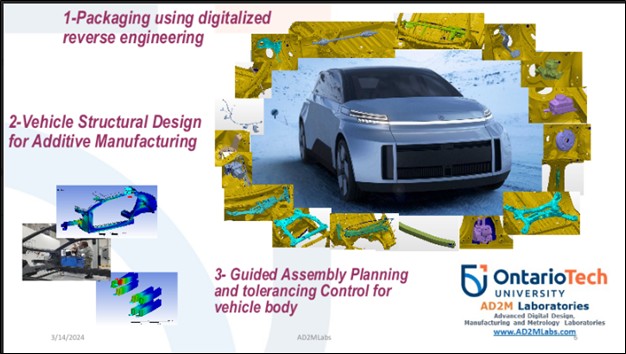

1st Place - Digitalization Packaging and Structural Design of Project Arrow

AD2M Labs - Ontario Tech University

Project Summary:

Project Arrow is a full-build, zero-emission concept vehicle, launched by the Automotive Parts Manufacturers’ Association (APMA) of Canada. Ontario Tech was the lead academic institution, to complete the engineering design and build phase of this national project. The submitted project involved the packaging, structural design, additives design for manufacturing of a 3D printed chassis, and development of a guided assembly procedure for the vehicle body. The project included work in various engineering research aspects, including structural design, digitalization in design, digital inspection and modelling, additive manufacturing, aerodynamics, electrification, energy efficiency, battery management, autonomous driving, and cybersecurity.

Completing the vehicle involved interactively revising the overall packaging using digitalized reverse engineering to optimize the functionality and fit of the designed components, where the AD2M Labs team modelled and digitalized more than 50 assemblies, sub-assemblies, and parts of the Arrow’s engineering design, each covering various functionalities, details, and complexities. The detailed design and the process planning for the additive manufacturing of the vehicle chassis and structure were completed using a novel and customized additive manufacturing technology.

The project is a promising Electric Vehicle approach to reducing the carbon footprint and CO2 emissions in the transportation sectors and a demonstration of Canadian national willingness to move faster toward a clean, sustainable and safe environment. Many of the research students who participated in the project will have the opportunity to share their knowledge and continue to develop these technologies at various companies and in industries within the GTA.

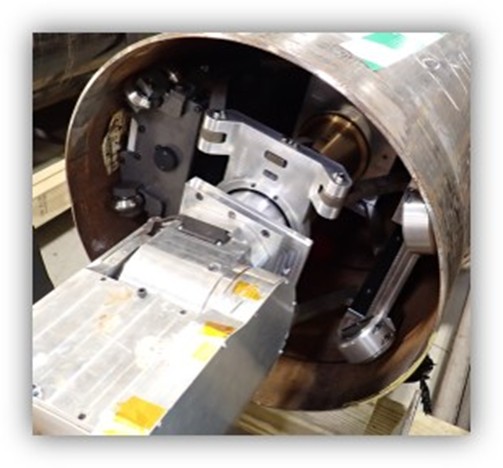

2nd Place - LSW Sensor

Intero Integrity Services

Project Summary:

This project provided a solution for a Sensor Module in an integrated system aboard the Intero Integrity “Pipe Explorer” family of robots. This sensor module deploys an innovative sensing technology (a nondestructive testing technique) to scan and detect seam weld anomalies in a diverse set of live Natural Gas pipelines, detecting leakage on both the internal and external surfaces of the pipeline. This technology does not require pipeline flow to be reduced or shut down during operation and can be deployed effectively for inspection of the natural gas pipeline assets of the energy sector to safeguard people and protect the environment.

The project addresses environmental sustainability through enhancement of the safety of pipeline assets and inspecting the areas that need to be addressed and repaired. The impact is to guarantee the safe operation of energy transmission through gas pipelines and public safety. Finding early signs of damage and carrying out the necessary repairs is also critical to preventing more damage and extra cost of repair.

This Gas Pipeline inspection project, driven by “Pipe Explorer” robots originally made at the Toronto-based Invodane Engineering at Intero Integrity, brings economic benefits to the GTA by creating engineering jobs and extending expertise knowledge of engineering in the field of Robotics and sensing technology.